Carbon Bonded Silicon Carbide Crucible yeInduction choto

PRODUCT FEATURES

Superior Thermal Conductivity

Iyo yakasarudzika musanganiswa wesilicon carbide uye graphite inovimbisa nekukurumidza uye yunifomu kupisa, zvakanyanya kuderedza pasi panguva yekunyungudika.

Kunyanya Tembiricha Resistance

Iyo yakasarudzika musanganiswa wesilicon carbide uye graphite inovimbisa nekukurumidza uye yunifomu kupisa, zvakanyanya kuderedza pasi panguva yekunyungudika.

Durable Corrosion Resistance

Iyo yakasarudzika musanganiswa wesilicon carbide uye graphite inovimbisa nekukurumidza uye yunifomu kupisa, zvakanyanya kuderedza pasi panguva yekunyungudika.

ZVAKAITIKA ZVINHU

| No | Model | O D | H | ID | BD |

| 78 | IND205 | 330 | 505 | 280 | 320 |

| 79 | IND285 | 410 | 650 | 340 | 392 |

| 80 | IND300 | 400 | 600 | 325 | 390 |

| 81 | IND480 | 480 | 620 | 400 | 480 |

| 82 | IND540 | 420 | 810 | 340 | 410 |

| 83 | IND760 | 530 | 800 | 415 | 530 |

| 84 | IND700 | 520 | 710 | 425 | 520 |

| 85 | IND905 | 650 | 650 | 565 | 650 |

| 86 | IND906 | 625 | 650 | 535 | 625 |

| 87 | IND980 | 615 | 1000 | 480 | 615 |

| 88 | IND900 | 520 | 900 | 428 | 520 |

| 89 | IND990 | 520 | 1100 | 430 | 520 |

| 90 | IND1000 | 520 | 1200 | 430 | 520 |

| 91 | IND1100 | 650 | 900 | 564 | 650 |

| 92 | IND1200 | 630 | 900 | 530 | 630 |

| 93 | IND1250 | 650 | 1100 | 565 | 650 |

| 94 | IND1400 | 710 | 720 | 622 | 710 |

| 95 | IND1850 | 710 | 900 | 625 | 710 |

| 96 | IND5600 | 980 | 1700 | 860 | 965 |

PROCESS Flow

1. Precision Formulation

High-purity graphite + premium silicon carbide + proprietary binding agent.

.

2.Isostatic Pressing

Density kusvika 2.2g/cm³ | Wall ukobvu kushivirira ± 0.3m

.

3.High-Temperature Sintering

SiC particle recrystallization inogadzira 3D network chimiro

.

4. Surface Enhancement

Anti-oxidation coating → 3 × yakanatsiridza corrosion resistance

.

5.Yakasimba Hunhu Kuongorora

Yakasarudzika kodhi yekutevera yehupenyu hwakazara traceability

.

6.Safety Packaging

Shock-absorbent layer + Moisture barrier + Reinforced casing

.

PRODUCT APPLICATION

Gas Melting Furnace

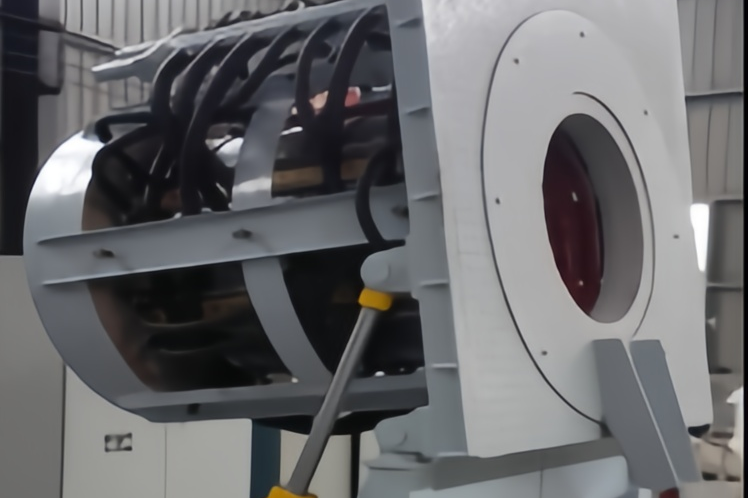

Induction Melting Furnace

Resistance Melting Furnace

SEI TISARUDZEI

FAQS

Q1: Ndezvipi zvakanakira silicon carbide graphite crucibles ichienzaniswa neyechinyakare graphite crucibles?

✅Higher Temperature Resistance: Inogona kumira 1800 ° C kwenguva refu uye 2200 ° C kwenguva pfupi (vs. ≤1600 ° C ye graphite).

✅Upenyu Hwakareba: 5x zviri nani kupisa kuvhunduka kuramba, 3-5x yakareba avhareji yehupenyu hwesevhisi.

✅Zero Contamination: Hapana kabhoni kupinda, kuve nechokwadi chakanyungudutswa simbi kuchena.

Q2: Ndedzipi simbi dzinogona kunyungudutswa mune idzi crucibles?

▸Common Metals: Aluminium, mhangura, zingi, goridhe, sirivha, nezvimwe.

▸Reactive MetalsLithium, sodium, calcium (inoda Si₃N₄ coating).

▸Refractory Metals: Tungsten, molybdenum, titanium (inoda vacuum / inert gasi).

Q3: Ko macrucibles matsva anoda pre-kurapwa usati washandiswa?

Mandatory Baking: Zvishoma nezvishoma kupisa kusvika 300 ° C → bata kwemaawa maviri (inobvisa hunyoro hwasara).

First Melt Recommendation: Nyungudusa batch yezvakaraswa zvinhu kutanga (inoumba danda rekudzivirira).

Q4: Nzira yekudzivirira sei crucible kupaza?

Usambofa wakachaja zvinhu zvinotonhora mune inopisa crucible (max ΔT <400 ° C).

Mwero wekutonhodza mushure mekunyunguduka <200°C/awa.

Shandisa mbambo dzakatsaurirwa dzecrucible (dzivisa mechanical impact).

Q5: Nzira yekudzivirira sei crucible cracking?

Usambofa wakachaja zvinhu zvinotonhora mune inopisa crucible (max ΔT <400 ° C).

Mwero wekutonhodza mushure mekunyunguduka <200°C/awa.

Shandisa mbambo dzakatsaurirwa dzecrucible (dzivisa mechanical impact).

Q6: Ndeipi iyo shoma yekuodha huwandu (MOQ)?

Standard Models: 1 chidimbu (mienzaniso iripo).

Custom Designs: 10 zvidimbu (CAD mifananidzo inodiwa).

Q7: Ndeipi nguva yekufambisa?

⏳In-Stock Items: Inotakurwa mukati memaawa makumi mana nemasere.

⏳Custom Orders: 15-25mazuvayekugadzira uye mazuva makumi maviri ekuumba.

Q8: Ungaziva sei kana crucible yakundikana?

Kutsemuka> 5mm pamadziro emukati.

Metal kupinda kudzika> 2mm.

Deformation> 3% (yera yekunze dhayamita shanduko).

Q9: Iwe unopa kutungamira kwekunyungudika?

Heating curves yesimbi dzakasiyana.

Inert gasi kuyerera rate Calculator.

Slag kubvisa vhidhiyo tutorials.