Foundry Crucibles yeAluminium Inoenderera Kukandira Maitiro

Zvakanakira uye preheating maitiro esilicon carbide crucible

Nhanganyaya:

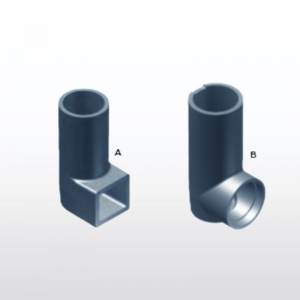

Foundry crucibles inoita basa rakakosha mumaindasitiri ekunyungudutsa uye kukanda maindasitiri, ichipa yakakwirira-tembiricha kuramba uye kusimba. YeduFoundry Crucibles, inowanikwa mune zvese zviri zviviri silicon carbide uye graphite akasiyana, anogadzirwa kuti asangane nezvinodiwa zvinodikanwa zvevagadziri vesimbi, kuve nechokwadi chekushanda kwakakwana mumashandisirwo akasiyana-siyana.

Zvigadzirwa zveChigadzirwa zve Foundry Crucibles:

| Feature | Tsanangudzo |

|---|---|

| Thermal Conductivity | Yakagadzirwa kubva kune yakakwira yekupisa conductivity zvinhu, aya macrucibles anofambisa kukurumidza kupisa conduction. |

| Hupenyu Hurefu Hwebasa | Silicon carbide crucibles inopa hupenyu hwesevhisi 2-5 nguva refu pane yakasarudzika yevhu sarudzo graphite. |

| High Density | Yakagadzirwa uchishandisa yepamusoro isostatic kudzvanya kuve nechokwadi cheunifomu density uye isina hurema-isina zvinhu. |

| High Strength | High-pressure molding techniques inowedzera simba, zvichiita kuti ive yakakodzera kune zvakanyanya mamiriro ezvinhu. |

| Corrosion Resistance | Yakagadzirwa kuti imirisane nekuora kwesimbi yakanyungudutswa, ichiwedzera kushandiswa kwayo. |

| Low Slag Adhesion | Minimal slag adhesion pamadziro emukati inoderedza kupisa kupisa uye inodzivirira kuwedzera. |

| High Temperature Resistance | Inokwanisa kushanda mumatembiricha kubva ku400 ° C kusvika 1700 ° C, yakakodzera kune dzakasiyana siyana dzekunyungudutsa. |

| Kusvibiswa kwakaderera | Yakagadzirwa kuti ideredze tsvina inokuvadza panguva yekunyungudutswa kwesimbi. |

| Metal Anti-Corrosion | Iine zvakakosha zvinhu zvinodzivirira zvinobudirira simbi oxidation. |

| Kuchengetedza Simba uye Kuchengetedzwa Kwezvakatipoteredza | Kufambisa kupisa kwakanaka kunobatsira kuderedza kushandiswa kwemafuta uye kuderedza kusvibiswa kwemarara. |

| High Oxidation Resistance | Yepamberi antioxidant nzira dzinochengetedza kutendeseka kwecrucible panguva yekushandiswa. |

Kukosha kwePreheating process:

Preheating yakakodzera kwakakosha kuti uve nechokwadi chehupenyu hurefu hwesilicon carbide crucibles. Kuregeredza danho iri kunogona kutungamirira kukukundikana nguva isati yakwana. Heino nzira inokurudzirwa preheating:

- 0°C-200°C:Oiri inononoka kupisa kwemaawa mana, magetsi anononoka kupisa kweawa imwe.

- 200°C-300°C:Simba uye kupisa zvishoma nezvishoma kwemaawa mana.

- 300°C-800°C:Kupisa zvishoma nezvishoma kwemaawa mana.

- Mushure meKudzima Kwevira:Tevedzera zvishoma nezvishoma reheating nhungamiro kuchengetedza crucible kutendeseka.

Product Applications:

Yedu yekutanga crucibles inosiyana-siyana uye inogona kushandiswa kune akasiyana maindasitiri, kusanganisira:

- Aluminium Alloy Kugadzira:Yakakosha yemhando yepamusoro aluminium alloy kugadzirwa.

- Metalworking Maitiro:Zvishandiso zvakakosha zvema foundries uye simbi recyclers.

Maintenance Tips:

Kuti uwedzere hupenyu uye kuita kweako ekutanga crucibles, tevedzera anotevera maitiro ekugadzirisa:

- Kugara uchichenesa kudzivirira kuungana kwezvinosvibisa.

- Preheating yakakodzera isati yashandiswa yega yega kudzivirira kupisa kutyisa.

Mibvunzo Inowanzo bvunzwa (FAQ):

- Ndeapi tembiricha anogona kutsungirira foundry crucibles?

Macrucible edu akagadzirirwa kutsungirira tembiricha inosvika 1700 degrees Celsius. - Preheating yakakosha sei?

Preheating yakakosha kudzivirira kutsemuka uye kuve nechokwadi chekuita kwakakwana. - Ndeipi kuchengetedza inodiwa kune foundry crucibles?

Nguva dzose kuchenesa uye preheating kwakakodzera kwakakosha pakuchengetedza crucible kutendeseka.

Mhedziso:

Kushandisa yeduFoundry Cruciblesichavandudza kunyunguduka kwako nekuita simbi. Mamiriro avo epamusoro, akasanganiswa neakakosha preheating process, inovimbisa kusimba uye kuita kwakakwana munzvimbo dzinoda.

Call to Action (CTA):

Bata nesu nhasi kuti uwane kurudziro yemunhu or kuisa odha yakokune edu emhando yepamusoro foundry crucibles. Simudza maitiro ako ekugadzira simbi nemhinduro dzedu dzakavimbika uye dzinoshanda!