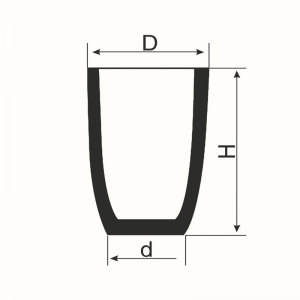

Material:

YeduCylindrical Crucibleinogadzirwa kubva kune isostatically yakadzvanywa silicon carbide graphite, chinhu chinopa yakasarudzika yepamusoro-tembiricha kuramba uye yakanakisa yekupisa conductivity, ichiita chishandiso chakakosha chekugadzira maindasitiri ekunyungudutsa.

- Silicon Carbide (SiC): Silicon carbide inozivikanwa nekuomarara kwayo kwakanyanya uye kuramba kwekupfeka nekuora. Inogona kumirisana nepamusoro-tembiricha yemakemikari maitiro, ichipa kugadzikana kwepamusoro kunyangwe pasi pekunetseka kwekupisa, izvo zvinoderedza njodzi yekutsemuka panguva yekushanduka kwekushisa kamwe kamwe.

- Natural Graphite: Natural graphite inopa yakasarudzika yekupisa conductivity, kuve nechokwadi chekukurumidza uye yunifomu kupisa kugovera mukati mecrucible. Kusiyana nechinyakare chevhu-based graphite crucibles, yedu cylindrical crucible inoshandisa yakakwirira-kuchena kwechisikigo graphite, iyo inovandudza kupisa kwekufambisa kushanda uye kuderedza kushandiswa kwesimba.

- Isostatic Kudzvanya Tekinoroji: Iyo crucible inoumbwa uchishandisa advanced isostatic kudzvanya, kuve nechokwadi cheunifomu density isina mukati kana kunze kukanganisa. Iyi tekinoroji inosimudzira kusimba uye kutsemuka kuramba kweiyo crucible, ichiwedzera kusimba kwayo munzvimbo dzepamusoro-tembiricha.

Kuita:

- Superior Thermal Conductivity: Iyo Cylindrical Crucible inogadzirwa kubva kune yakakwira thermal conductivity zvinhu zvinobvumira kukurumidza uye kunyangwe kupisa kugovera. Izvi zvinowedzera kushanda kweiyo smelting process apo ichideredza kushandiswa kwesimba. Kuenzaniswa neyakajairwa crucibles, kupisa kwemafuta kunovandudzwa ne15% -20%, zvichitungamira kune yakakosha kuchengetedza mafuta uye nekukurumidza kutenderera kwekugadzira.

- Yakanakisa Corrosion Resistance: Yedu silicon carbide graphite crucibles inopokana zvakanyanya kune inoora mhedzisiro yesimbi yakanyungudutswa nemakemikari, kuve nechokwadi kugadzikana uye hupenyu hurefu hweiyo crucible panguva yekushandiswa kwenguva refu. Izvi zvinovaita vakanaka pakunyungudutsa aluminium, mhangura, uye akasiyana simbi alloys, kuderedza kugadzirisa uye kutsiva frequency.

- Upenyu Hwebasa Hwakawedzerwa: Nehupamhi hwepamusoro uye yakasimba-yakasimba chimiro, hupenyu hwe cylindrical crucible yedu ndeye 2 kusvika ku5 nguva yakareba kupfuura yevhu yevhu graphite crucibles. Iko kupikisa kwepamusoro kuputsa uye kupfeka kunowedzera hupenyu hwekushanda, kuderedza nguva yekudzikisa uye kutsiva mari.

- Yakakwira Oxidation Resistance: Iyo yakanyatso kuumbwa zvinhu kuumbwa zvinobudirira kudzivirira oxidation yegraphite, kuderedza kuderera pakupisa kwakanyanya uye kuwedzera hupenyu hwecrucible.

- Superior Mechanical Strength: Nekuda kweiyo isostatic yekutsikirira maitiro, iyo crucible inozvirumbidza yakasarudzika mechanical simba, ichichengetedza chimiro chayo uye kusimba munzvimbo dzepamusoro-tembiricha. Izvi zvinoita kuti ive yakanakira kunyungudutsa nzira inoda kudzvanywa kwepamusoro uye kugadzikana kwemichina.

Product Advantages:

- Material Benefits: Kushandiswa kwechisikigo graphite uye silicon carbide inogonesa yakakwira yekupisa conductivity uye kushora kusagadzikana, ichipa kushanda kusingaperi munzvimbo dzakaoma, dzepamusoro-tembiricha.

- Yakakwirira-Density Chimiro: Isostatic yekutsikirira tekinoroji inobvisa mukati ma voids uye makatsemuka, zvakanyanya kuvandudza iyo crucible kusimba uye simba panguva yekuwedzera kushandiswa.

- High-Temperature Kugadzikana: Inokwanisa kutsungirira tembiricha inosvika 1700 ° C, crucible iyi yakanakira nzira dzakasiyana dzekunyungudika nekukanda zvinosanganisira simbi uye alloys.

- Kushanda Kwesimba: Hunhu hwayo hwepamusoro hwekutamisa kupisa hunoderedza kushandiswa kwemafuta, nepo zvinhu zvine hushamwari zvinoderedza kusvibiswa nemarara.

Kusarudza yedu yepamusoro-inoshanda Cylindrical Crucible haingo wedzera kunyungudutsa kwako zvakanaka asi zvakare kuderedza mashandisirwo esimba, kuwedzera hupenyu hwemidziyo, uye kudzikisa mutengo wekugadzirisa, pakupedzisira uchivandudza kugadzira.

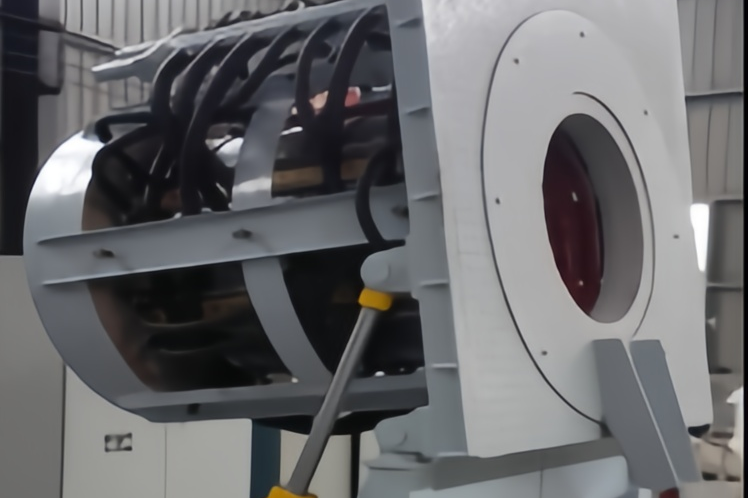

Mumaindasitiri emazuva ano ekugadzira simbi uye kudzokorodza, kupisa induction yave nzira inosarudzika yekushanda uye kwakanyatso kunyungudika. Sarudzo yecrucible inotora basa rakakosha mukuona kuti maitiro aya anofamba zvakanaka, kunyanya mumoto wekupinza. Isu takagadziraInduction Heating Cruciblesuchishandisa isostatic kudzvanya tekinoroji kupa isingaenzaniswi kuita mune izvi zvinoda maapplication.

Kusiyana neyakajairwa crucibles, iyo inogona kunetsekana nemagineti mumagetsi ekuisa, macrucibles edu akagadzirirwa kugadzira kupisa kuburikidza nemagineti induction. Iyi tsvarakadenga haingowedzere kushanda kwesimba chete asi zvakare inowedzera hupenyu hweiyo crucible, ichiita iyo sarudzo yakakodzera kune maindasitiri akadai searuminiyamu kudzokorodza uye kukanda simbi.

Iwo magineti emhando dzema crucibles aya anonyanya kukosha kune vashandisi ve induction furnaces, uko kugona kuitisa kupisa kuburikidza nekupinza kunogona kuwedzera zvinoshamisa kugona kwese kwekuita. Izvi hazvingochengetedze nguva chete asiwo zvinoderedza mutengo wesimba, zvichiita kuti ive mhinduro inodhura kumabhizinesi.

Zvishandiso zveInduction Heating Crucibles

- Aluminium Recycling Indasitiri:

- Muindasitiri yealuminium yakadzokororwa, corrosion resistance yakakosha nekuda kwekuomarara kwemamiriro ezvinhu. Macrucibles edu akanyatsogadzirirwa kubata nharaunda idzi, achipa hupenyu hunodarika crucibles dzeEurope neanopfuura 20%.

- Iyo yakakwira yekupisa conductivity inovimbisa kukurumidza kunyungudika nguva, iyo inowedzera kugadzirwa uye inoderedza kushandiswa kwesimba.

- Induction Furnaces:

- Traditional crucibles kazhinji inoshaya magineti zvimiro, izvo zvinogona kuguma nekusashanda zvakanaka kana zvichishandiswa mu induction furnaces. Yedu induction heat crucibles inogadzirwa nemagnetic heat capabilities, zvichireva kuti crucible pachayo inogadzira kupisa, inovandudza kuita kwese kwese kwekuita uye nekudzikisira mutengo wesimba.

- Nenguva yehupenyu inopfuura gore rimwe, macrucibles aya anonyanya kupfuura mamwe, achideredza nguva yekudzikira uye kutsiva mutengo.

- Mamwe Metal Melting Applications:

- Ingave yemhangura, zinc, kana sirivheri yekunyunguduka, macrucibles edu anopa kuita kwakavimbika, kuve nechokwadi chemhedzisiro inowirirana mumaindasitiri akasiyana.

Kugadzirisa uye Mazano Ekushandisa eInduction Heating Crucibles

Kuti uwedzere hupenyu uye kushanda zvakanaka kweInduction Heating Crucible yako, zvakakosha kutevedzera mashandisiro akakodzera uye maitiro ekugadzirisa:

- Preheating: Zvishoma nezvishoma pisa crucible kune yaunoda tembiricha kudzivirira kuvhunduka kwekushisa.

- Kuchenesa: Gara uchichenesa crucible kubvisa zvisaririra zvinogona kukanganisa kuita uye kupfupisa hupenyu.

- Kuchengeta: Chengetedza macrucibles munzvimbo yakaoma, inotonhorera kudzivirira kuratidzwa kune unyoro kana zvinhu zvinopisa zvinogona kukanganisa zvinhu nekufamba kwenguva.

Aya maitiro anozobatsira kuona kuti crucible yako inoshanda nepamusoro-soro kwenguva yakareba, ichideredza kuwanda kwekutsiva uye kugadzirisa.

Product Promotion

Isu tinodada nekupa Induction Heating Crucibles yakagadzirirwa kusimba kwakanyanya uye kuita. Macrucibles edu anoratidza isostatic yekutsikirira tekinoroji, iyo inovimbisa kufanana uye simba, zvichiita kuti iwedzere kupikisa kuvhunduka kwekupisa uye kushushikana kwemagetsi. Nekugona kuburitsa kupisa kuburikidza nemagineti induction, macrucibles edu akagadzirirwa zvakanangana induction choto kunyorera, uko iko kurongeka uye kushanda nesimba kwakakosha.

Customization Sarudzo: Isu tinonzwisisa kuti indasitiri yega yega ine yakasarudzika zvinodiwa. Ndosaka isu tichipa zvizere customizable crucibles, akarongedzerwa kusangana neako chaiwo ekushanda zvinodiwa. Kunyangwe iwe uchida chimiro chakasiyana, saizi, kana kuumbwa, timu yedu yakagadzirira kushanda newe kugadzira iyo yakakwana mhinduro.

Tsigiro yeTekinoroji: Chikwata chedu chakazvipira chinopa yakazara tekinoroji rutsigiro kuti ikubatsire iwe kuwana zvakanyanya kubva kune ako macrucibles. Kubva pakumisikidzwa kwekutanga kuenda kune inoenderera mberi yekugadziridza zano, isu tiri pano kuti tive nechokwadi chekuti maitiro ako anofamba zvakanaka uye nemazvo.

Call to Action

Kana iwe uri kutarisa kuti uwedzere kushanda kweyako induction yekudziya maitiro, yedu Induction Heating Crucibles ndiyo mhinduro yakakwana. Iine isostatic yekutsikirira tekinoroji, yepamusoro magineti yekudziya zvivakwa, uye yakawedzera hupenyu hurefu, aya macrucibles anopa kuvimbika uye kuita bhizinesi rako rinoda kuramba riri mberi mumusika wemakwikwi.

Bata nesu nhasi kuti udzidze zvakawanda nezve yedu yakagadziridzwa crucible mhinduro uye maitiro avanogona kuvandudza maitiro ako ekugadzira.