Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

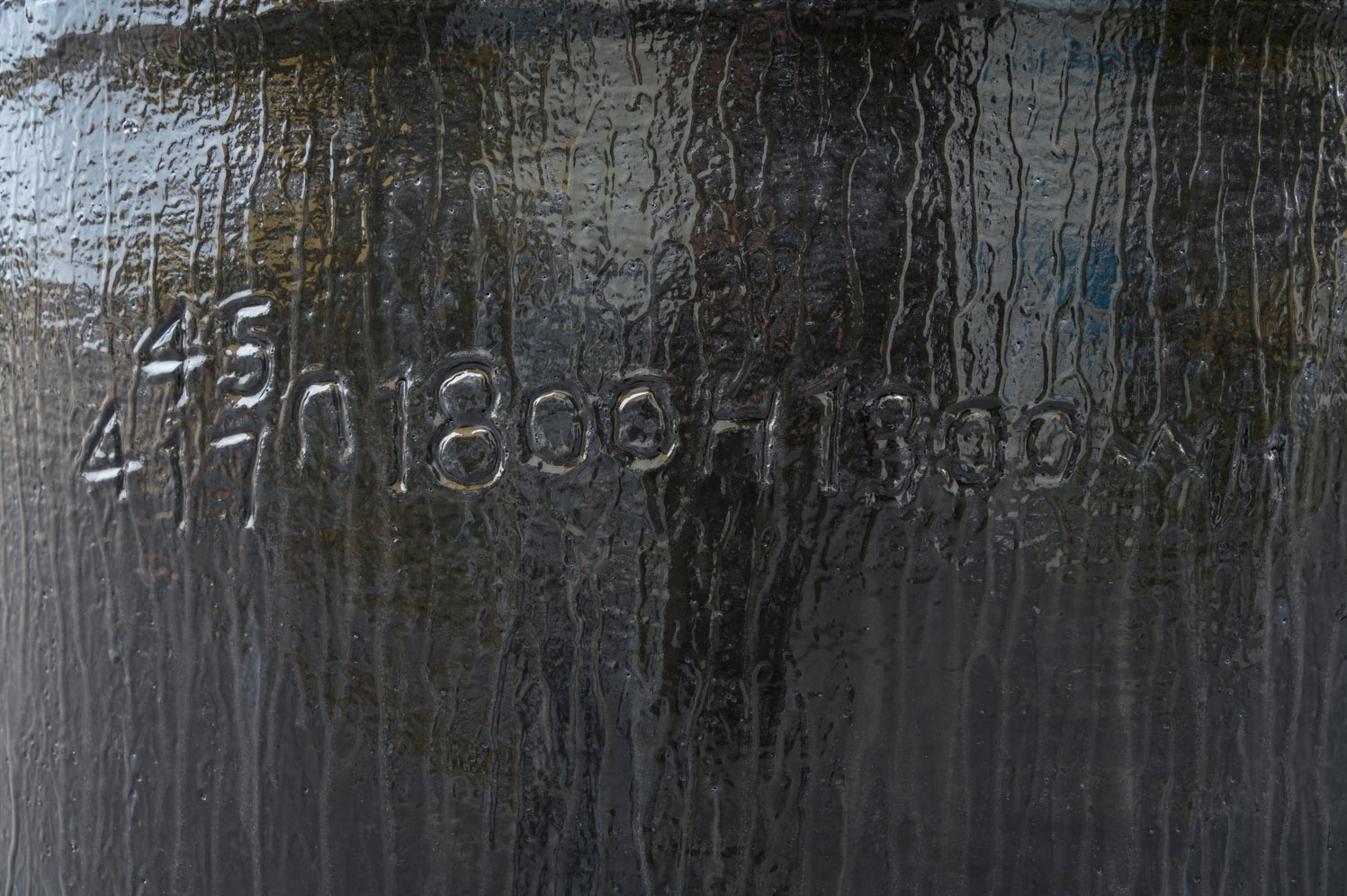

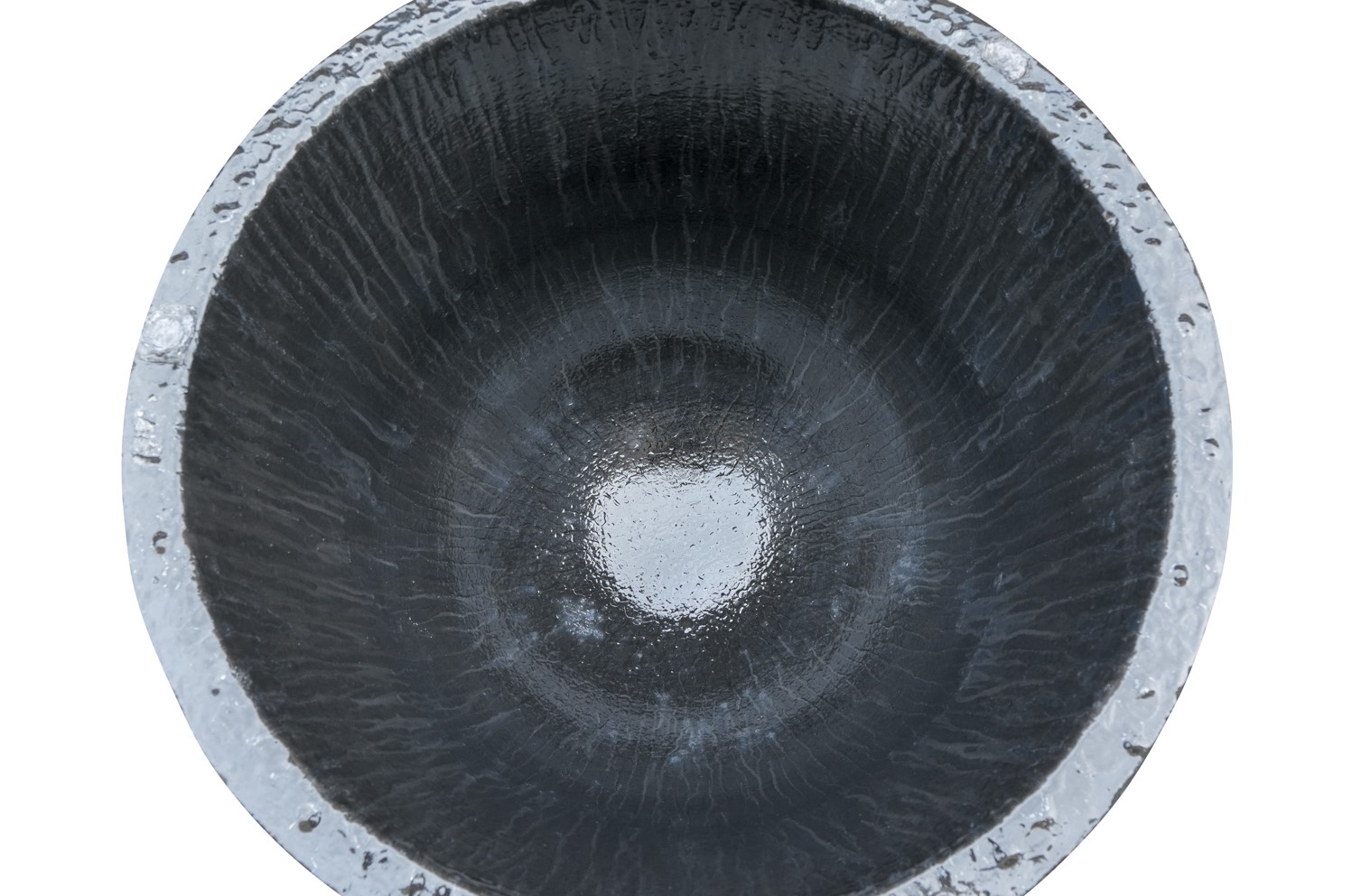

Melting crucible for non-ferrous metal Melting and Casting

PRODUCT FEATURES

Rapid Melting

High thermal conductivity graphite material inovandudza kupisa kwemafuta ne30%, zvakanyanya kuderedza nguva yekunyunguduka.

Superior Thermal Shock Resistance

Resin-bonded tekinoroji inomira nekukurumidza kupisa uye kutonhora, ichibvumira yakananga kuchaja pasina kutsemuka.

Exceptional Durability

High mechanical simba rinopikisa kukanganiswa kwemuviri uye kukukurwa kwemakemikari kwehupenyu hurefu hwebasa.

ZVAKAITIKA ZVINHU

| Graphite / % | 41.49 |

| SiC / % | 45.16 |

| B/C / % | 4.85 |

| Al₂O₃ / % | 8.50 |

| Bulk density / g·cm⁻³ | 2.20 |

| Zviri pachena porosity / % | 10.8 |

| Kupwanya simba/ MPa (25 ℃) | 28.4 |

| Modulus yekuputika/ MPa (25 ℃) | 9.5 |

| Moto kuramba tembiricha/ ℃ | >1680 |

| Thermal shock resistance / Nguva | 100 |

| No | Model | H | OD | BD |

| RA100 | 100# | 380 | 330 | 205 |

| RA200H400 | 180# | 400 | 400 | 230 |

| RA200 | 200# | 450 | 410 | 230 |

| RA300 | 300# | 450 | 450 | 230 |

| RA350 | 349# | 590 | 460 | 230 |

| RA350H510 | 345# | 510 | 460 | 230 |

| RA400 | 400# | 600 | 530 | 310 |

| RA500 | 500# | 660 | 530 | 310 |

| RA600 | 501# | 700 | 530 | 310 |

| RA800 | 650# | 800 | 570 | 330 |

| RR351 | 351# | 650 | 420 | 230 |

PROCESS Flow

1. Precision Formulation

High-purity graphite + premium silicon carbide + proprietary binding agent.

.

2.Isostatic Pressing

Density kusvika 2.2g/cm³ | Wall ukobvu kushivirira ± 0.3m

.

3.High-Temperature Sintering

SiC particle recrystallization inogadzira 3D network chimiro

.

5.Yakasimba Hunhu Kuongorora

Yakasarudzika kodhi yekutevera yehupenyu hwakazara traceability

.

4. Surface Enhancement

Anti-oxidation coating → 3 × yakanatsiridza corrosion resistance

.

6.Safety Packaging

Shock-absorbent layer + Moisture barrier + Reinforced casing

.

PRODUCT APPLICATION

Inokodzera simbi dzakawanda dzisina-ferrous

Melt Aluminium

Melt Copper

Melt Gold

SEI TISARUDZEI

FAQS

Q1: Ko Iyo Crucible Cover inogona kuderedza mari yesimba here?

A: Ndizvozvo! Inoderedza kupisa kurasikirwa, kucheka kushandiswa kwesimba kusvika ku30%.

Q2: Ndeapi mavira anowirirana?

A: Inoshandiswa zvakasiyana-siyana-yakakodzera kupinza, gasi, uye mavira emagetsi.

Q3: Is graphite silicon carbide yakachengeteka kune tembiricha yakakwira?

A: Hongu. Kugadzikana kwayo uye kugadzikana kwemakemikari kunoita kuti ive yakakwana kune yakanyanyisa mamiriro.

Q4: Nzira yekudzivirira sei crucible kupaza?

Usambofa wakachaja zvinhu zvinotonhora mune inopisa crucible (max ΔT <400 ° C).

Mwero wekutonhodza mushure mekunyunguduka <200°C/awa.

Shandisa mbambo dzakatsaurirwa dzecrucible (dzivisa mechanical impact).

Q5: Nzira yekudzivirira sei crucible cracking?

Usambofa wakachaja zvinhu zvinotonhora mune inopisa crucible (max ΔT <400 ° C).

Mwero wekutonhodza mushure mekunyunguduka <200°C/awa.

Shandisa mbambo dzakatsaurirwa dzecrucible (dzivisa mechanical impact).

Q6: Ndeipi iyo shoma yekuodha huwandu (MOQ)?

Standard Models: 1 chidimbu (mienzaniso iripo).

Custom Designs: 10 zvidimbu (CAD mifananidzo inodiwa).

Q7: Ndeipi nguva yekufambisa?

⏳In-Stock Items: Inotakurwa mukati memaawa makumi mana nemasere.

⏳Custom Orders: 15-25mazuvayekugadzira uye mazuva makumi maviri ekuumba.

Q8: Ungaziva sei kana crucible yakundikana?

Kutsemuka> 5mm pamadziro emukati.

Metal kupinda kudzika> 2mm.

Deformation> 3% (yera yekunze dhayamita shanduko).

Q9: Iwe unopa kutungamira kwekunyungudika?

Heating curves yesimbi dzakasiyana.

Inert gasi kuyerera rate Calculator.

Slag kubvisa vhidhiyo tutorials.

Nyaya Chidzidzo #1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Nyaya Chidzidzo #2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Testimonials

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. Pellentesque aliquet feugiat tellus, et feugiat tortor porttitor vel. Nullam id scelerisque magna. Curabitur placerat sodales placerat. Nunc dignissim ac velit vel lobortis.

- Jane Doe

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. Pellentesque aliquet feugiat tellus, et feugiat tortor porttitor vel. Nullam id scelerisque magna. Curabitur placerat sodales placerat. Nunc dignissim ac velit vel lobortis. Nam luctus mauris elit, sed suscipit nunc ullamcorper ut.

- John Doe