Kana zvasvika kune yakakwirira-tembiricha kugadzirisa, sintering, kupisa kurapwa uye kristaro kukura kwesimbi, ceramics nezvimwe zvinhu, sarudzo of crucibleinoita basa rinokosha. Crucibles midziyo yakakosha inoshandiswa mumhando dzakasiyana dzemaindasitiri, uye kusarudza iyo chaiyo crucible zvinhu inogona kukanganisa zvakanyanya kushanda uye mhedzisiro yemaitiro aya. Muchisumo chechigadzirwa ichi, tichaongorora mutsauko uripo pakati pesilicon carbide uye graphite crucibles, tichitarisa maitiro avo akasiyana, hupenyu hwebasa, mutengo, uye huwandu hwemashandisirwo.

Silicon carbide crucible:

Silicon carbide crucibles inogadzirwa nesilicon carbide zvinhu, iyo inozivikanwa nekunaka kwayo kwepamusoro tembiricha yekudzivirira uye kushora. Aya ma crucibles anoshandiswa zvakanyanya mukupisa-kupisa sintering, kupisa kupisa uye kristaro kukura maitiro emasimbi, ceramics nezvimwe zvinhu. Iyo yakaoma zvimiro zvesilicon carbide inoita kuti ive yakanaka kune maapplication uko kunyanyisa tembiricha uye nharaunda dzinoparadza zvakajairika. Nekudaro, zvinofanirwa kucherechedzwa kuti zvichienzaniswa ne graphite crucibles, silicon carbide crucibles ine hupenyu hupfupi hwesevhisi, kunyanya pasi pekushisa kwakanyanya uye nekuora. Iyo tsika yesilicon carbide crucibles kuita oxidize uye ablate ichakanganisa hupenyu hwavo hwesevhisi. Kunyangwe masilicon carbide crucibles ane hupenyu hupfupi hwesevhisi, akakosha mumaindasitiri anoda kugadziriswa kwezvinhu zvinoparadza zvakanyanya uye zvekupisa zvakanyanya, zvichivaita sarudzo yekutanga yemagetsi uye optoelectronic kugadzira zvikumbiro.

Graphite crucible:

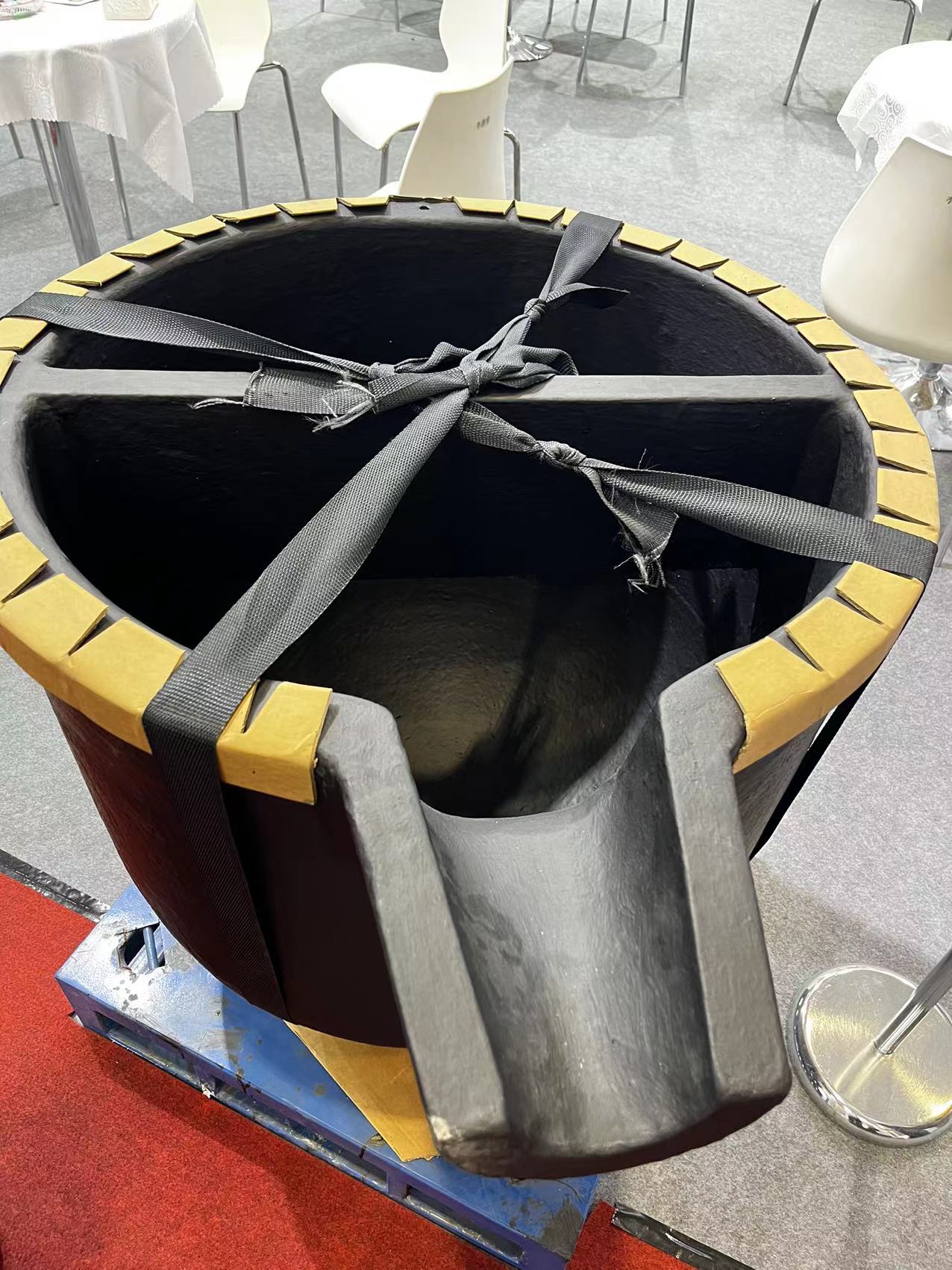

Kusiyana neizvi, magirafu crucibles anogadzirwa ne graphite zvinhu uye anoshandiswa zvakanyanya mukugadziriswa kwesimbi uye isiri-simbi zvinhu. Graphite crucibles anozivikanwa nekupokana kwavo neoxidation, ablation uye tembiricha yakakwira, zvichikonzera hupenyu hwakareba hwesevhisi kana uchienzaniswa nesilicon carbide crucibles. Uku kusimba kunoita kuti girafu crucibles sarudzo inodhura-inoshanda yezvikumbiro zvinosanganisira kupisa kupisa uye kukura kwekristaro kwezvinhu zvakasiyana-siyana. Iko kugona kwe graphite crucibles, pamwe nehupenyu hwavo hurefu hwesevhisi, inovaita sarudzo yakakurumbira kune iwo maindasitiri anotsvaga akavimbika uye anogara macrucibles mukugadzira kwavo maitiro.

Sarudza crucible chaiyo:

Sarudzo pakati pesilicon carbide uye graphite crucibles pakupedzisira zvinoenderana nezvinodiwa chaizvo zvekushandisa. Kunyangwe silicon carbide crucibles ine yakanakisa kupokana kune yakakwira tembiricha uye inoora nharaunda, iyo inodhura zvakanyanya nekuda kwemaitiro ekugadzira uye mutengo wezvinhu. Graphite crucibles, kune rumwe rutivi, ane mari yakawanda, ane hupenyu hurefu hwebasa, uye akakodzera kune zvakasiyana-siyana zvekushandisa, kunyanya izvo zvinosanganisira kugadzirwa kwezvinhu, kupisa kupisa, uye kukura kwekristaro.

Kupfupisa, silicon carbide crucibles uye graphite crucibles ane zvawo zvakanakira uye zvisingabatsiri. Paunenge uchisarudza crucible yeimwe application, chaiyo yekushanda mamiriro, zvinhu zvinodiwa, uye bhajeti zvinonetsa zvinofanirwa kutariswa. Kwepamusoro-tembiricha, corrosive material processing, kana kugadzira muminda yemagetsi neoptoelectronics, silicon carbide crucibles ndiyo yekutanga sarudzo. Kusiyana neizvi, pakurapa kwekupisa uye kukura kwekristaro yezvinhu zvakajairika, magirafu crucibles anopa mhinduro inodhura uye yakasimba.

Pa [zita rekambani yako], tinopa huwandu hwakazara hwekabhoni graphite crucibles, graphite crucibles, silicon carbide graphite crucibles uye silicon graphite crucibles kusangana nezvinodiwa zveindasitiri zvakasiyana. Ma crucibles edu akagadzirirwa kumhando yepamusoro-soro, kuve nechokwadi chekushanda kwakakwana uye kuvimbika mumhando dzakasiyana dzekugadzira. Kunyangwe iwe uchida macrucibles epamusoro-tembiricha sintering, kupisa kupisa kana kukura kwekristaro, yedu chigadzirwa renji inopa kuita kwakasiyana uye kusimba kunodiwa kutsigira mashandiro ako.

Sarudza [Zita reKambani Yako] yemhando yepamusoro crucibles ine yakasarudzika mashandiro uye hupenyu hwesevhisi, zvichikubvumidza iwe kuti uwane mibairo yakatanhamara mumaindasitiri ako maitiro. Bata nesu nhasi kuti tiongorore yedu yakazara huwandu hwemacrucibles uye uwane mhinduro yakakwana kune yako chaiyo application zvinodiwa.

Nguva yekutumira: Mar-27-2024