Nhanganyaya

Kusarudza iyo chaiyo yekukweretwa yakakosha kune inoshanda simbi yekunyungudza uye yekukanda maitiro. Kunyangwe iwe urikushanda naSilicon Carbide Crocbiles or Graphite Crcudues, kunzwisisa kwavoinoshandisa, tembiricha, uyeZVINOKOSHA ZVINOKOSHAinogona kusimudzira kubereka uye kuita. Munyaya ino, isu tichafukidza zvese zvaunoda kuziva, kubvaGraphite Crocucle Saizi to Silicon Carbide Bonding, uchiri kupindura mibvunzo sengeChii chinoshandiswa kusimbirira simbi?uyeSilvert tembiricha inonyungudika?

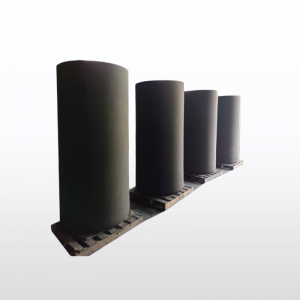

Pepa

1. Chii chinonzi silicon carbide uye graphite croclibiles?

- Silicon Carbide Crocbiles.

- Graphite Crcudues.

2. ZVINOKOSHA ZVINOKOSHA UYE ZVINHU

- Tembiricha:

Inozivikanwa mhando Tembiricha yekudziya (° C) Silicon carbide Kusvikira 1650 ° C Graphite Kusvika 3000 ° C - Zvishandiso. Inowanzoshandiswa mumishongo yekugadzira, quentries, uye inoenderera ichikanda maitiro.

- Kusimba:

- Silicon carbide carblibles ari anodziya-anodziya-anodzivirira uye akagadzirirwa kazhinji ekudzora kudzora.

- Graphite crculies inogadziriswa nemakemikari uye inogona kubata nharaunda dzakanganisa.

3. Graphite inochinjika saizi uye simbi kuenderana

- Saizi:

Graphite cripments inowanikwa muhukuru hwakasiyana siyana kuti ienderane zvidiki-zviyero kusvika kumaindasitiri ekushandisa.Saizi Kugona Zvidiki 1-5 kg Pakati 6-20 kg Hombe 21 kg uye pamusoro - Kuwirirana kwesimbi:

Metal Type Inonyungudika pfungwa (° C) Yakakurudzirwa Inokanganiswa Copper ~ 1085 Silicon carbide kana graphi Sirivheri ~ 961 Silicon carbide kana graphi Goridhe ~ 1064 Graphite

4. Silicon carbide uye graphite croctic inoshandiswa zvinoshandiswa

- Silicon Carbide Crocbiles: Yakanakira simbi dzinoda kukurumidza kudzora miteji, senge mukuenderera mberi kwekukanda maitiro.

- Graphite Crcudues: Inosarudza yakakwira-tembiricha mitezo uye seyakafananaladle ivhu, Shroud Manipulators, uyeTundish Stopersnekuda kwekuita kwavo kwakanyanya.

5. Kuchengeta uye Kuchengeta Matipi

Kukurisa zvinokatyamadza hupenyu uye kushanda zvakanaka:

- Dzivisa kuchinja kamwe kamwe kwekushisa: Dzivirira marara anokonzerwa ne thermal kuvhunduka.

- Kugara kuchenesa: Bvisa slag uye zvakasara mushure mekushandiswa kwega kwega.

- Kuchengetedza kwakakodzera: Ramba uine yakaoma, yakanyorova-isina-yakasununguka nharaunda kudzivirira kusvibiswa kwezvinhu.

Zvikataurwa zvevatengi vehunyanzvi

- Q: Chii chinoshandiswa kunyungudika simbi seshongo nesirivheri?

A: Silicon carbide uye graphite cripment inowanzo shandiswa nekuda kwemakona avo akanyanya ekunyungudika uye akanakisa anogadzikana. - Q: Ndeipi ichinyungudutsa chetatu chendarira uye graphite?

A: Mhangura melts panenge 1085 ° C, nepo graphite cripments inogona kutsungirira kupisa kunosvika mazana matatu ° c. - Q: Ndechipi chinowanzoitika chakanakira kukanda maindasitiri?

A: Grathite Crculibles inosarudzwa kuti isimbiswe yakakwirira-tembiricha, nepo silicon carbide carblibless yakanakira kudzvinyirira kudzora nzvimbo munzvimbo dzekugadzira.

Nei uchisarudza?

Isu tinopa maindasitiri-anotungamira mhinduro mukatiSilicon carbideuyeGraphite Crcudues.

| Zvakanakira zvedu | Nei Zvichikosha |

|---|---|

| Dzakasiyana siyana dzehukuru | Kubva padiki-huwandu hwekushandiswa kwemaindasitiri. |

| Zvigadzirwa zvePreemium | Yakakwirira-mhando siliciumcarbide uye yakachena graphite inochengetedza kuvimbika kwenguva refu. |

| Tsika Dzinogadzirisa | Magadzirirwo akagadziridzwaLald shrouds, yakadzika yekupinda nozzles, uye zvimwe zvishandiso zvekukanda. |

| Nyanzvi Rutsigiro | Makumi emakore eruzivo mukatiSimbi Kugadzirauyemetal casting crunobles. |

Wagadzirira kusimudzira maitiro ako ekukanda? Taura nesu nhasi kune yakakwirira-performance croctibles yakagadzirirwa kuzadzisa zvido zvako zvebhizinesi!

Kutumira Nguva: Nov-19-2024